Barrow Engineering was established in 1953 by Edward James Smith with a staff of three. Barrow Engineering is based in Peakhurst, Sydney NSW and has now expanded into 1200m2 of factory floor space, incorporating a comprehensive welding and manufacturing plant. Our 20 staff operate 10 CNC Machines, 16 hours a day, six days a week.

Barrow Engineering is committed to delivering cutting-edge manufacturing solutions with a focus on quality, precision, and meeting the evolving needs of Australia’s defense, mining and construction industries.

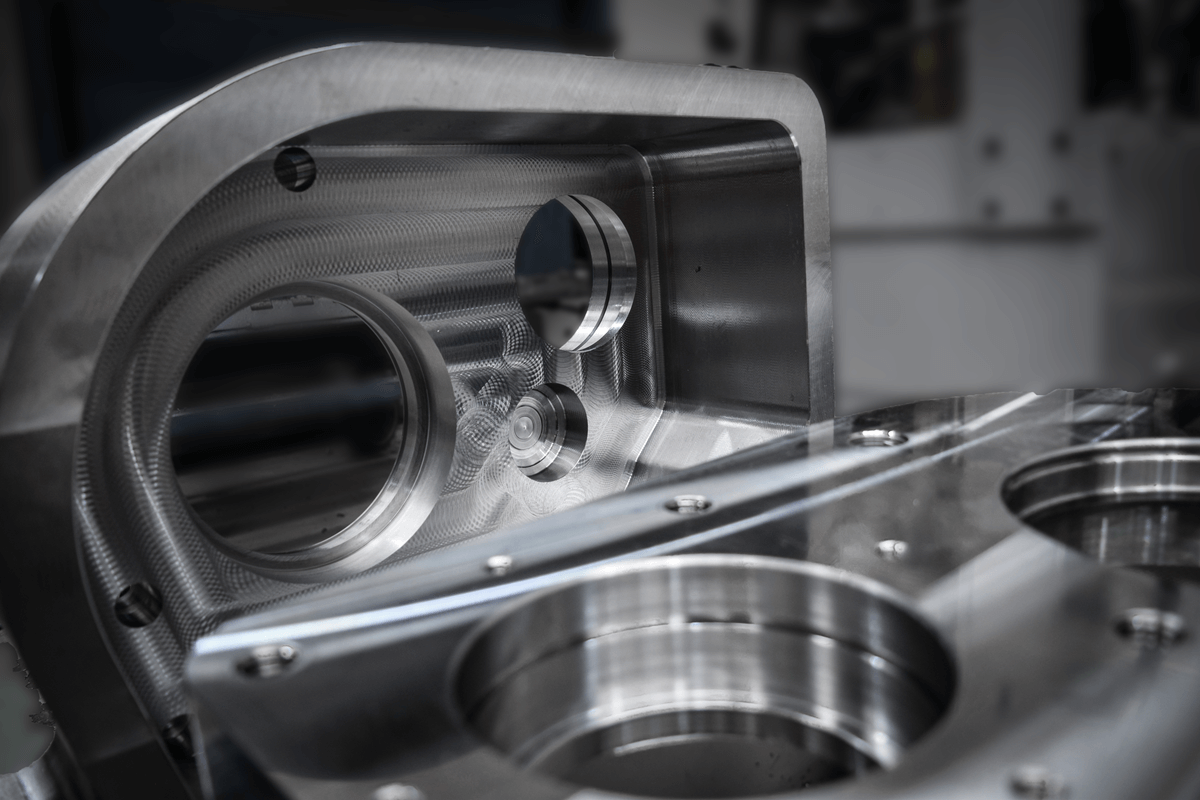

Our team’s expertise in CAD CAM design, CNC machining and reverse engineering enables us to solve complex challenges and produce precision components that meet the highest industry standards.

Our comprehensive CAD CAM services offer precise designs and simulations that optimise the manufacturing process, ensuring accuracy and quality.

Our 3-4 axis CNC machining centers operate around the clock, providing unparalleled precision for components in defense, mining, and construction.

Our Team uses state of the art technology, we provide reverse engineering services that allow us to recreate and improve existing parts. Using advanced technologies like CMM machines, CAD software, and precision CNC machining, we deliver results that are accurate, efficient, and tailored to your needs.

Our AS 9100 D certification reflects our unwavering commitment to quality. Each project is subjected to rigorous planning from point of quote all the way through to packing and dispatch.

At Barrow Engineering, we take pride in our state-of-the-art CNC machinery to deliver precision components for Australia’s leading industries. Our investment in advanced manufacturing technology ensures that we meet the exacting standards of the defense, mining, and construction sectors, while maintaining efficient production timelines.

Our Partners

Interested in learning more about how Barrow Engineering can support your business? Contact our team today to discuss your specific project requirements.

Head Office: 11/63 Norman Street, Peakhurst, Sydney, NSW 2210

Phone: +61 2 9153 0133

Email: [email protected]

If you are interested in applying for any of the positions we are currently recruiting for, please visit: Careers, or Email [email protected]

Copyright 1953 -2025 Barrow Engineering | All Rights Reserved | Terms & Conditions