BARROW ENGINEERING

Barrow Engineering was established in 1953′ by Edward James Smith with a staff of three. Barrow Engineering is based in Sydney NSW and has now expanded into 1200m2 of factory floor space, incorporating an advanced manufacturing CNC department; with a variety of multi-axis machine centres. Complimented by a dedicated quality and reverse engineering department.

We specialise in CNC Machining for government science technology and research. While having extensive experience across the mining, rail and high voltage industries.

Barrow Engineering has the capability and knowledge to machine a variety of materials, including:

- Plastics

- Brass, copper, bronze, aluminium

- Stainless steel, titanium, high-tensile steel

Barrow Engineering welcomes the opportunity to discuss your engineering requirements.

CNC MACHINING CAPABILITIES

CNC Machining

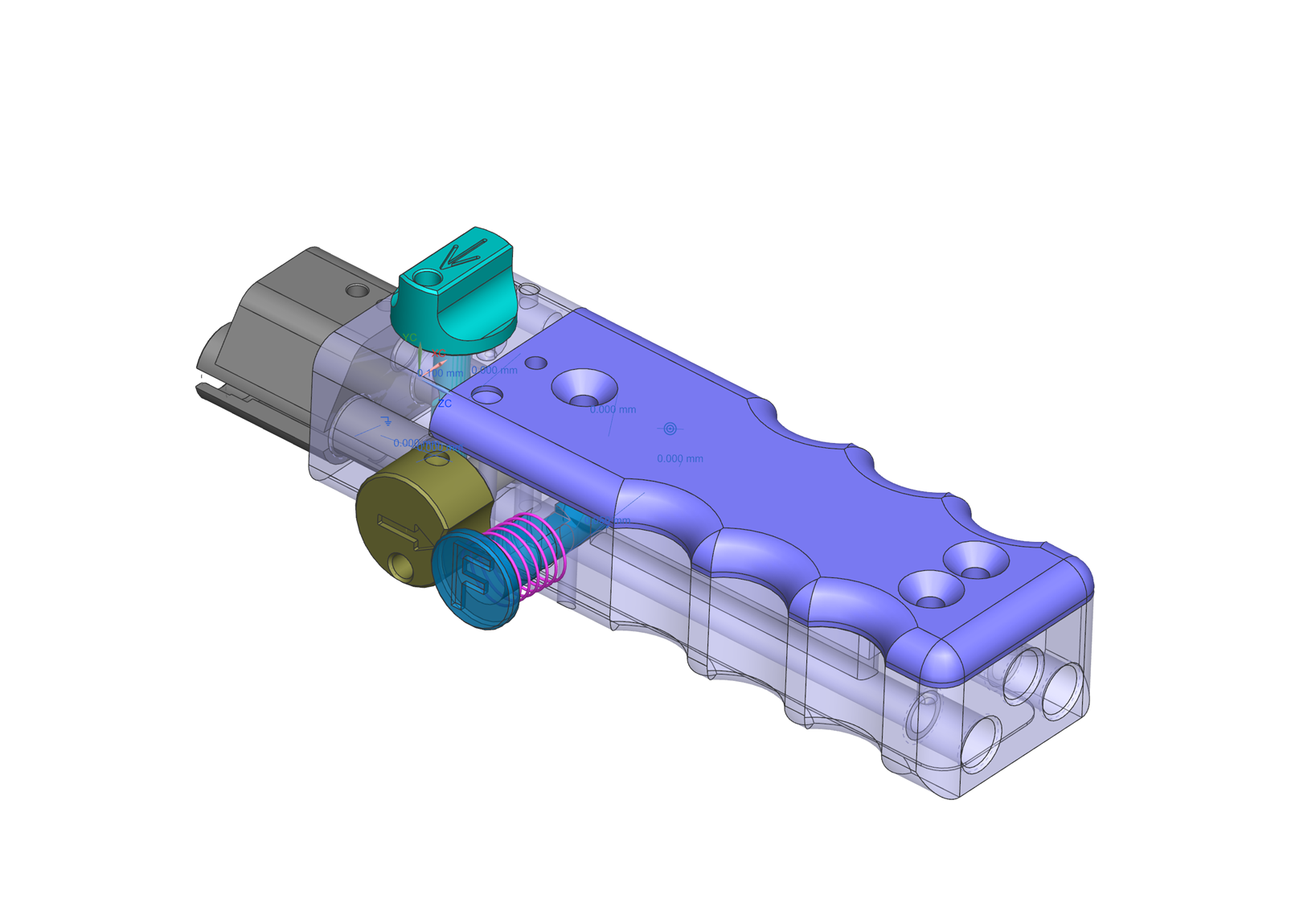

CNC Multi-Axis (3/4/5/9) including CNC Twin Spindle Mill Turn Lathes. 3 and 4 Axis Milling. Automatic loading and unloading. Zeiss CMM. On machine temperate control probing.

CAD/ CAM & REVERSE ENGINEERING

Quality Department / Reverse Engineering

Barrow Engineering is equipped with a NX Space Cam 3D Modelling Software which supports all stages of product development from conceptualisation (CAID), to design (CAD), to analysis (CAE), to manufacturing (CAM).

With quality assured processes throughout all production to AS1199, from incoming material, manufacturing, inspection, validation and shipping. Automatically generated inspection sheets and all material; additive manufacturing processes certificates available.