About the author : Focus

What is a CNC Machine?

What is a CNC milling machine?

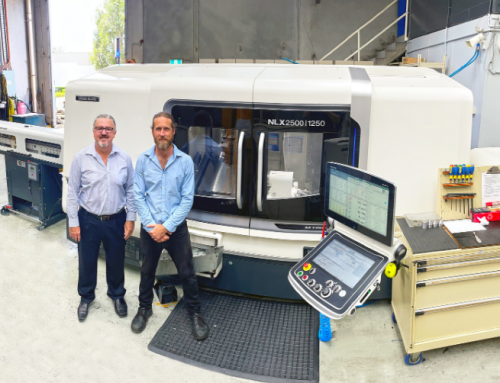

Barrow Engineering specialises in CNC machining, which is a process for manufacturing which utilises software to control the movement of factory machinery and tools. Short for ‘Computer Numerical Control’, the process can be applied to machinery like grinders and routers, but we largely use CNC for mills and lathes.

CNC machining dates back to the 1940s, when motors were utilised to control the movement of tools, and as technology advanced, the mechanisms and functional outcomes improved in speed and accuracy. Today, the process is entirely electronic.

Utilising CNC machining means that we’re able to complete complex, three-dimensional cutting tasks from a single range of prompts. The prompts used in CNC machining is considered a more reliable process than manual controls, which mean staff are required to operate, prompt and guide the machining tools. While we love the team, the CNC machines remove the element of human error and allow for ultimate precision at every step of the manufacturing process.

That process begins when the required cuts are programmed into the software, and the corresponding machinery and tools respond by carrying out the tasks as specified. The placement and movement of the tool in the process is dictated by the program, but the code itself is created by programmers and input via small keyboards. There is also the capacity to retain the programming in the memory of the machine, and newer prompts for additional changes can be added via CAD drawings and programming, aka revised codes.

In simplest terms, CNC machining allows us to pre-program the position and speed of the functions of a tool, and run them in precise, repetitive cycles.

The position of the machine and control of the movement is designated via either an open or closed-loop system. Open-loop allows for a single direction of motion, while closed provides for the correction of errors via feedback, revising irregularities. Open-loop is most commonly used for low speed and force movement, while closed-loop allows for speed and accuracy for larger-scale applications.

Barrow Engineering offers CNC machining for the following operations:

CNC Mills

CNC mills are the computer numerically controlled version of the traditional style manual mill. Starting with the minimum three axes (X, Y and Z axis’s), CNC mills can now operate up to simultaneous five axes. The increase in axis allows the machine more ability to create intricate shapes and surface finishes on a variety of designs along with eliminating multiple setups and machining operations.

With the addition to CAD/CAM software in the manufacturing world, the ability to program these machines has developed extensively in recent years. The majority of programming is completed off the machine and “posted” to the device itself. This allows a draftsperson to create a design and model it to their specifications, and the manufacturer can then develop their program and tool paths directly from the customers model, eliminating more room for human error and help utilise the CNC machine to its full potential.

Lathes

Lathe machining can utilise CNC function when creating pieces in a circular process, offering high velocity and the utmost precision, similarly to CNC mills. Using CNC lathes means that it is possible to create intricate designs that wouldn’t be possible with the manual functions of the lathes.